High Flow Inlet Manifold - Z20LEx

Prototype V1 |

Plastic Prototype V2 |

Plastic Prototype V3 |

CAD Drawing - V4 |

Flow Testing |

Stephan Klasen, our tuning partner and mapping engineer, has produced numerous high powered Z20LEx cars and for some time has had the most powerful Z20LEx engined car at 659BHP in his crazy Speedster. His various builds continually found that the standard inlet manifold starts flow inefficiently on high power applications over 350 BHP.

Using this knowledge gained from his Speedster and other builds, the high flow manifold is the culmination of a project Stephan started over 2 years ago. The aim was to design a manifold that fitted all versions & applications of the Z20LEx engine to produce good high end power whilst not sacrificing all the bottom and mid range end power.

Prototype Version 1 was a simple design with its squashed plenum it produced good high end bhp however more work was needed with the plenum for more even air distribution.

Prototype Version 2 featured a dual plenum design this produced good air distribution and good bhp numbers due to is short inlet tract it was good for power to 8000+ rpm, however when tried with the plastic prototype V2 this power was at the cost of low end torque and mid range power. So was considered too extreme for most applications.

Prototype Version 3 was the beginnings of the manifold we ended up with. The inlet tracts were made longer to keep a good torque spread, whilst the pre-resonance chamber made larger and improved in shape for enhanced air flow. A costly plastic prototype was again made for testing.

This proved invaluable as the bottom end power and torque was vastly improved, however we felt that the top end power could be further enhanced with larger ports. This proved the best balance between low end torque and power and high end power, showing improved power / boost ratio at 455 bhp (we did not dare run it at higher boost than this as it was making some nasty noises due it being made from plastic, whilst others in the workshop feared 1st degree plastic lacerations!!)

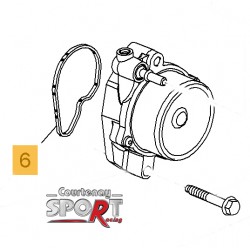

Version 4 was the final version with only subtle mods being made to the pre-resonance to port transition whilst externally some hardware mounting points altered.

We have also tried the manifold on an engine equipped with a VXR K04 turbo whilst not expecting any huge gains with an engine already running 290 to 300 bhp we were pleased to see the inlet manifold fitted. Once mapped to suit the inlet manifold showed power gains from 5,700 rpm, with gains of 10 bhp at 6,000rpm, 23 bhp at 6,500 rpm and 29bhp at 7,000 rpm.

In the past this has only been achieved by fitting cams the result of this can lead to an unwanted lumpy idle, whilst fitting an inlet manifold and leaving the standard cam profile leaves the idle smooth as standard.

High Flow Inlet Manifold designed for ALL Z20LEx petrol turbo engines 1351

The Courtenay Klasen High Flow Inlet Manifold is the result of many months of development and testing, and after numerous prototypes the final product was developed.

Designed to remove the restriction in the original inlet manifold that restricts air flow into the engine. This manifold will allow the engine to breathe fully, and has been designed to increase power but not at the expense of mid range power and torque (for example, a shorter inlet manifold will give good power at extremely high end rpm i.e. 8,500 rpm but will lose mid range torque).

Ideal for fast road and track use.

Gains have been shown on Stage 3 300 bhp Astra VXR, on a K06 hybrid turbo (with no loss in mid range torque) and on full Garrett builds running for example a GT28/30/35 turbo unit, allowing the engine to continue to produce power well above 7,000 rpm.

From our experience we have found this to be a much more worthwhile upgrade to the Z20LEx engine than fitting a cams as an upgrade, as not only are the results better but there is no unwanted lumpy idle associated with high lift cams as this inlet manifold can be fitted whilst retaining the standard cams.

NB: Will require suitable mapping for maximum gains.

-250x250.jpg)